Metal roof restoration is an excellent way to extend the life of your commercial roof without the expense and disruption of full metal roof replacement. But while the idea of “do-it-yourself” (DIY) restoration might sound appealing—especially to cost-conscious building owners and maintenance crews—there are several crucial steps and pitfalls that DIYers often overlook. These mistakes can lead to poor results, costly repairs, and even roof failure down the line.

At SR Commercial Roofing, we understand the metal roof restoration process inside and out. Here’s a practical guide that shines a light on what DIY metal roof restorers miss and why professional expertise matters.

Step 1: The Importance of Proper Surface Preparation

A metal roof must be meticulously cleaned and prepped before any restoration coating can be applied. This means:

- Removing all dirt, rust, old coatings, and debris

- Treating rusted areas with rust inhibitors

- Repairing dents, seams, and flashing to create a smooth surface

Many DIYers skip or rush this step, using pressure washing alone or applying coatings over rust spots. This results in poor adhesion, blistering, and peeling coatings within months.

If the dirt, old coatings, and debris are not removed first, coatings will not adhere properly to the roof. Even if you want to repair a leak on the roof by caulking over it, if you do not thoroughly clean the surface first, the caulk will not last any significant length of time.

If rust is not removed, it can continue to deteriorate the roof’s metal underneath the caulk and coatings even though the roof appears to be in good condition when inspected.

If seams are not properly covered and flashing is not sealed to the roof, even a good coating will not prevent water from leaking into those unaddressed weak points.

Step 2: Choosing the Right Coating—not Just Any Paint

Not all coatings are made equal. Metal roof restoration requires specialized elastomeric or acrylic coatings designed to withstand UV rays, expand and contract with the metal, and resist corrosion.

Using general-purpose paint or cheaper roof sealants that crack and flake under UV rays after only a few years or offer little waterproofing can give a false sense of security. Low quality coatings lead to premature failures and repetitive repairs.

At SR Commercial Roofing, we use Conklin’s roof coatings because they have been used for the past 45 years on roofs and have proven time and again their efficacy at stopping leaks, preventing corrosion, and lasting for 20+ years.

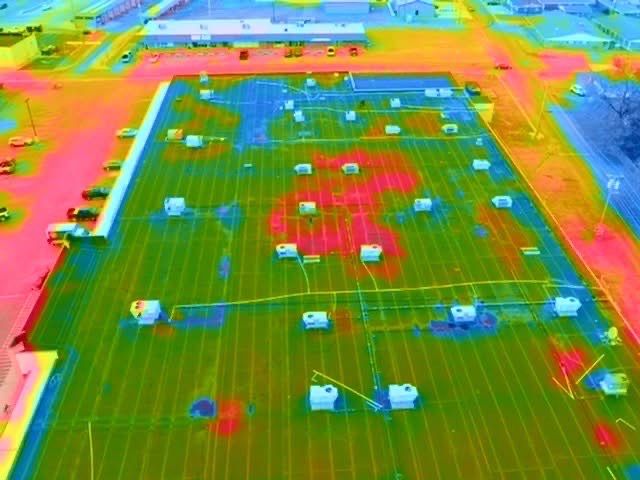

Thermal drone imaging shows where energy is escaping from the roof

Step 3: Detecting and Repairing Leaks Before Coating

Metal roofs often have hidden leaks at seams, fasteners, or penetrations. Restoring without locating and fixing these leaks means trapped water could cause damage underneath the coating. Ignoring small leaks results in ongoing water intrusion and potential structural damage.

We seal seams and protrusions with a durable fabric and coatings which mold to the seams and protrusions directing water to run off the roof instead of running into the building.

Additionally, if we inspect the roof using our thermal drone, we can also locate leaks or areas of poor insulation (which causes condensation within the building). Once we know which areas of the roof need additional attention, we can easily fix those areas by adding additional fabric or spraying foam (a hardy insulator) before coating the roof.

Conklin roofing materials

Step 4: Applying Coatings Correctly—Right Conditions and Multiple Coats

Coating application demands precise temperature, humidity, and wind conditions. Multiple thin coats—applied with the right tools—ensure durability and uniform protection.

DIY Mistake: Applying one thick coat, working in adverse weather, or using rollers/brushes not suited for elastomeric products leads to inconsistent protection and reduced lifespan.

At SR, we ensure that the coatings will adhere by planning around the weather. When spraying, the roof must be completely dry. But even after applying the coatings, they need a couple hours of warm, dry weather to cure before withstanding weather.

Freshly coated roof

Hidden Costs of DIY Shortcuts

- Premature Re-Roofing Costs: DIY failures require professional fixes sooner than expected.

- Energy Inefficiency: Poor coatings don’t reflect heat properly, leading to higher energy bills.

- Operational Disruptions: Peeling coatings can re-expose leaks and force unexpected business stoppages or emergency repairs.

- Warranty Voids: Manufacturers’ warranties often require professional installation to be valid.

Why Trust SR Commercial Roofing for Your Metal Roof Restoration (for either DIY or professional install)?

Our experienced crews follow rigorous prep and application processes and are even trained by our supplier, Conklin, in the best application practices.

We use premium coatings backed by manufacturer warranties, have seen the quality of our roofing system over the past 10+ years, and receive constant positive feedback on the quality of our installation.

Repairing your roof yourself is a challenging but doable task! If you’re interested in repairing your own roof, reach out to us at 608-844-4933, and we would be happy to answer any of your questions about roof repair.

Questions to Consider for Your Roof

- Has your roof been inspected for hidden leaks and surface rust beyond what meets the eye?

- Are you confident your coating product matches your roof and weather conditions?

- Would detailed walkthroughs of professional prep and application processes help you decide between DIY and pro services?