Spray-on roof coatings represent one of the most effective commercial roofing solutions available today, yet many property owners have never heard of them. At SR Commercial Roofing, many business owners haven’t heard of these innovative systems while all business owners are familiar with traditional metal or rubber roofs. The answer lies in history, market penetration, and research visibility. This blog explores the historical development of commercial roofing – particularly metal roofs, EPDM (rubber) roofs, and spray-on coatings – to explain why the latter remains somewhat of an industry secret despite its impressive benefits.

Ancient Beginnings of Roof Protection

The concept of protecting roofs with liquid applications isn’t new-it’s actually ancient. Archaeological evidence shows that as early as 3000 BC, ancient Egyptians utilized mixtures of beeswax, gelatin, and clay as varnishes and protective coatings on their roofs [1]. Beyond Egypt, ancient Asian architects applied lacquers and varnishes to buildings throughout China, Japan, and Korea by the 2nd century BC [1]. Historical dwellings across multiple continents featured cold-applied mixtures of clay, soil, and water to waterproof roofs and walls-techniques that still influence modern approaches.

These early innovations demonstrate humanity’s longstanding recognition that applying liquid protective layers to roofing surfaces provides enhanced durability and weather resistance – a principle that modern spray-on roof coatings have perfected.

Roofing History Overview

The Rise of Metal Roofing: A Two Centuries’ Head Start

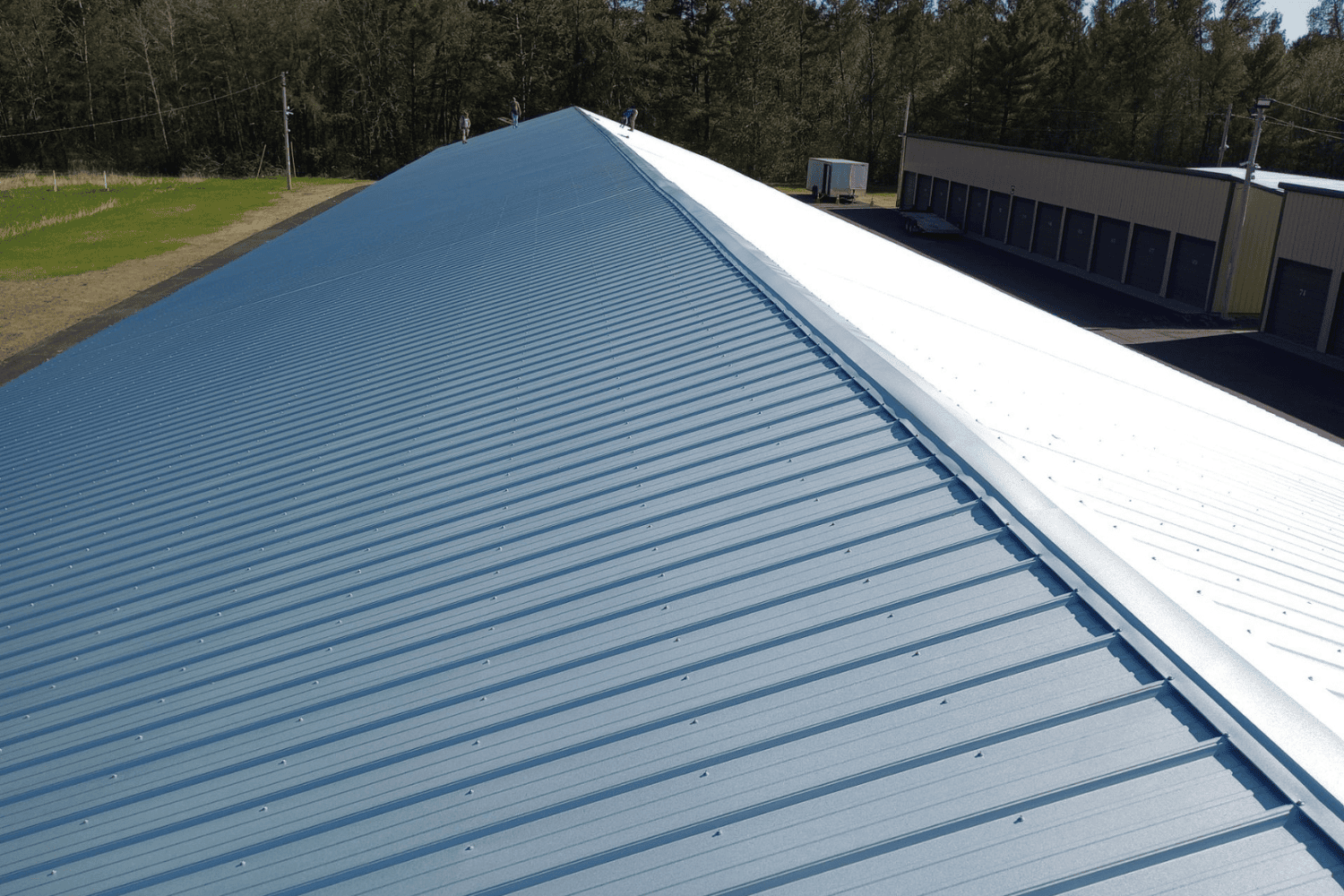

Figure 1 – New Metal Roof

Metal roofing enjoys widespread recognition largely because of its historical longevity in the marketplace. The first significant metal roof in America was installed in the early 1700s on Christ Church in Philadelphia, using lead to protect the church from fire [2]. This roof proved remarkably effective, helping the church become the only public building in Philadelphia to survive the Great Fire of 1721 [2].

The true innovation in metal roofing came in 1829 when Henry Palmer patented “indented or corrugated metallic sheets,” which added stiffness that allowed the sheets to be self-supporting when used as roofing [3]. After Palmer’s patent expired in 1843, corrugated galvanized iron (CGI) became popular worldwide [3]. The first corrugated metal roof in the United States was installed on the Dakota Territory Capitol Building in 1883 [2].

Metal roofing continued to evolve through the 19th and 20th centuries, becoming a staple in both commercial and residential construction. In the early 20th century, after military applications in World War I, corrugated metal roofing saw widespread adoption, though initially with low status until architects like Walter Gropius and Buckminster Fuller incorporated it into their designs [3].

This extensive history-spanning over 300 years-has given metal roofing a tremendous advantage in terms of market recognition and acceptance.

EPDM and Rubber Roofing: The Middle Child

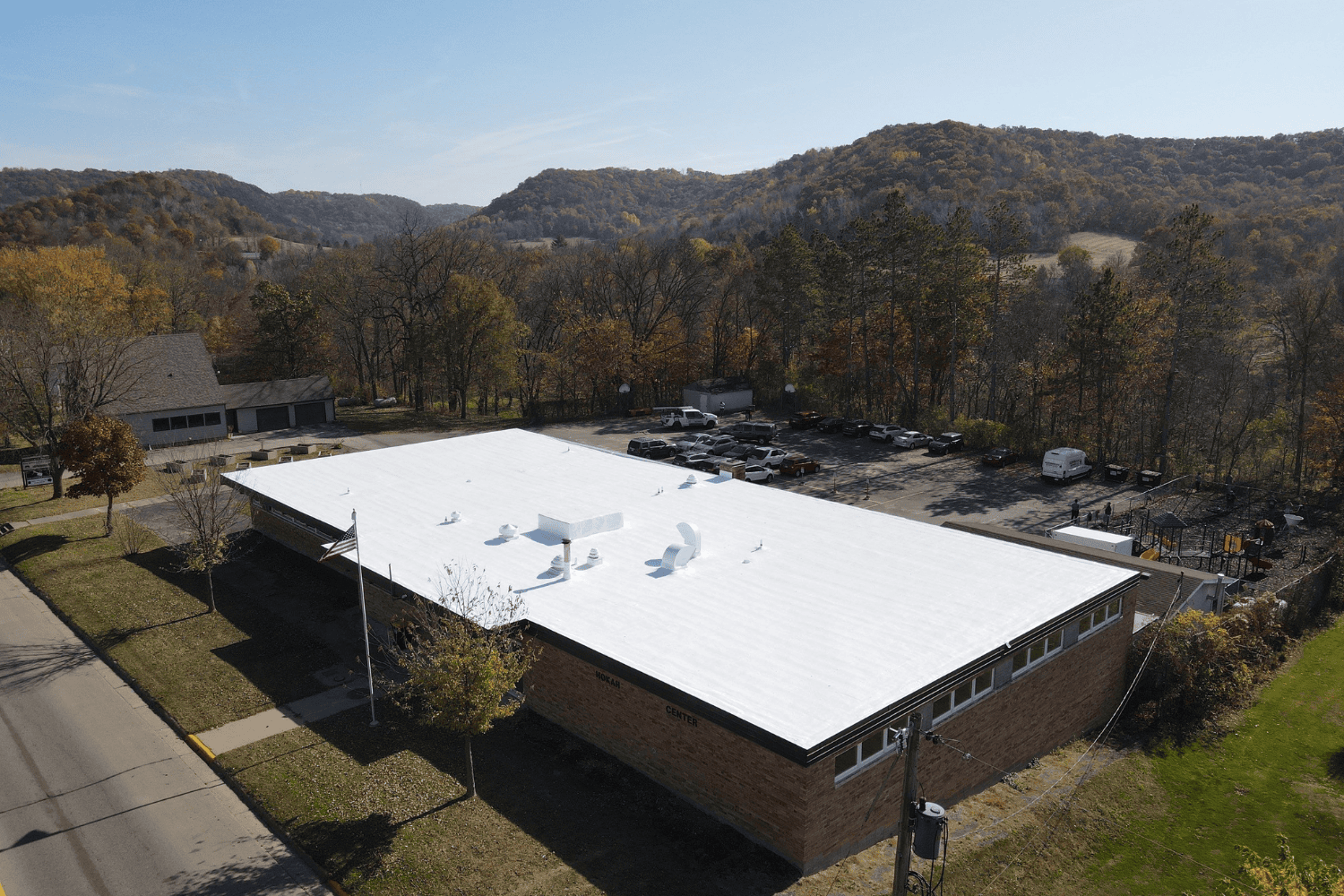

Figure 2 – Rubber Roof

Ethylene Propylene Diene Monomer (EPDM) or “rubber” roofing entered the commercial market much later than metal but still preceded spray-on systems in widespread adoption. White rubber roof membranes were introduced in 1987, making them relative newcomers compared to metal roofing [4].

Over the past three decades, significant advancements have improved rubber’s performance. When first introduced, rubber had respectable UV weathering resistance, but manufacturers continuously enhanced the formula. By the end of 1994, white rubber roofing had become much tougher, able to withstand some of the harshest weather tests out there-making it one of the most durable options for flat roofs [4].

The way these roofs are put together has also come a long way. Back in the late 1980s, installers used special cleaning solutions and sticky cements to seal the seams. Fast forward to 2001, and new products like specialized primers and double-sided seam tape made the process faster and easier. By 2005, the introduction of EPDM sheets with pre-applied tape meant that roofs could be installed more quickly and with even greater consistency and quality [4].

The Emergence of Modern Spray-On Roofing Systems

Figure 3 – Spray-on Roof – Red Top Coat

Spray-on roof coatings represent the newest major development in commercial roofing, with widespread use beginning only in the 1960s [5]. Interestingly, the very first roof coating was spray polyurethane foam (SPF), which initially showed promise for sealing cracks and preventing leaks but deteriorated quickly under UV radiation [4].

This challenge led manufacturers to experiment with protective coatings for the SPF or foam, eventually developing the advanced acrylic, silicone, and elastomeric coatings we use today. The 1960s marked a significant technological leap with the introduction of silicone roof coatings, which offered substantial improvements in durability, UV resistance, and weather resistance over traditional petroleum-based options [5].

The middle of the 20th century saw perhaps the most significant advancement in roofing materials with the incorporation of emulsion polymers [6]. These polymers created coatings with remarkable elasticity, adhesion, and durability-characteristics that make modern spray-on systems so effective.

Story Time: Conklin’s Early Roofing Jobs

Ben Welch, Conklin’s Senior Director, provided this video story which tells of the beginnings of spray-on roofing:

The Timeline Gap: Why Traditional Roofing Dominates

As the historical overview makes clear, spray-on roofing and rubber systems are relative newcomers to the roofing marketplace:

- Metal roofing: Used since the 1700s-1800s (200+ years)

- EPDM/rubber roofing: Mainstream since the late 1980s (35+ years)

- Spray-on roofing systems: Widespread commercial use since the 1960s (60+ years)

This timeline disparity gives traditional roofing methods a substantial advantage in terms of industry acceptance, contractor familiarity, and customer awareness. Spray-on roofing systems have been in the market for just a fraction of the time that metal roofing has existed, which partly explains their lower profile despite their excellent performance.

Limited Contractor Adoption Creates Knowledge Gap

Beyond the historical timeline, another significant factor in the relative obscurity of spray-on roofing is the specialized nature of its application. According to industry data, less than 25% of roofing services and contractors in the United States offer anything besides rubber and sheet metal roofing [7]. This limited contractor adoption creates a self-perpetuating cycle: fewer contractors offer the service, so fewer building owners learn about it, resulting in lower demand and fewer spray-on roofing contractors entering the space.

The specialized equipment, training, and expertise required for proper spray-on roof coating application further narrows the field of qualified contractors. At SR Commercial Roofing, we’ve made spray-on coatings our specialty because we recognize their tremendous value, but we’re in the minority within the broader roofing industry.

Research Disparities: The Untold Success Story

Perhaps the most significant factor keeping spray-on roof coatings from greater recognition is the research gap. Most roofing research focuses on “traditional” systems or lumps all roofing types together without highlighting the specific advantages of spray-on applications.

One notable exception demonstrates the remarkable potential of these systems: Texas A&M University conducted a study on 27 campus buildings with spray foam roofs and found they recouped the entire installation cost within just 4.5 years through energy savings alone [8]. Even more impressive, these roofing systems would continue providing protection and energy efficiency for another 15.5 years beyond the payback period.

Imagine if such research was more abundant and widely publicized. The energy efficiency benefits alone would likely drive much greater adoption of spray-on roofing systems in our increasingly sustainability-conscious marketplace.

The Functional Advantage: What Makes Spray-On Coatings Exceptional

Spray-on roofing systems function much like varnish does for old wood floors: they repair the surface they’re applied to, preserve it for years to come, and cost significantly less than full replacement. When spray-on foam is incorporated into the roofing system, buildings gain additional insulation that substantially reduces energy bills by preventing heat transfer [8].

Modern spray-on coatings offer numerous benefits that traditional roofing systems can’t match:

- Seamless application: Unlike traditional roofing with seams and joints that can fail, spray-on coatings create a continuous, monolithic membrane.

- Conformability: These coatings adapt to irregular shapes and penetrations, providing superior protection around roof features like HVAC units, pipes, and vents.

- Reflectivity: Many spray-on coatings offer exceptional solar reflectivity, significantly reducing cooling costs in warm climates.

- Extended roof life: By applying coatings to existing roofs, building owners can extend roof lifespans by 10-20 years without the expense and disruption of tear-off and replacement.

- Sustainability: Roof coatings reduce landfill waste by eliminating tear-off and can significantly decrease a building’s carbon footprint through improved energy efficiency.

Conclusion: The Future of Spray-On Roofing

Despite their relative obscurity compared to traditional roofing methods, spray-on roof coatings represent one of the most innovative and beneficial developments in commercial roofing history. Their lower profile stems not from performance shortcomings but from historical factors: they entered the market more recently than metal and EPDM systems, are offered by fewer contractors, and have been the subject of less published research.

As building owners increasingly prioritize energy efficiency, sustainability, and cost-effectiveness, spray-on roofing systems are positioned for greater recognition and adoption. The Texas A&M study demonstrating full cost recovery within 4.5 years offers a glimpse of the potential these systems hold.

At SR Commercial Roofing, we’ve specialized in spray-on roof coatings because we recognize their exceptional value proposition. While they may not yet have the name recognition of metal or single-ply roofing, their performance advantages make them the ideal solution for many commercial buildings. As awareness grows and more contractors develop expertise in these systems, we anticipate spray-on coatings will become increasingly mainstream in the commercial roofing industry.

The next time you consider your commercial roofing options, remember that sometimes the best solutions aren’t necessarily the most familiar ones-they might just be the industry’s best-kept secret.

Citations:

[1] https://gc-roofing.com/roof-coating-a-historical-perspective/

[2] https://www.gen819.com/the-history-of-metal-roofing/

[3] https://en.wikipedia.org/wiki/Metal_roof

[4] https://www.carlislesyntec.com/en/Resources/Media/Blog-Landing-Page/SpecTopics/2020/04/06/White-EPDM-History-and-Innovation

[5] https://www.rubberized.com/the-evolution-of-roof-coatings-a-historical-perspective/

[6] https://www.islandmetals.com/history-of-metal-roofing.html

[7] https://altaroofinginc.com/the-evolution-of-the-metal-roof/

[8] https://butlermfgparts.com/blog/standing-seam-roof-evolution