Introduction to Spray Foam Roofing

Spray foam roofing is revolutionizing commercial roofing by combining insulation and waterproofing into one seamless system. Spray foam roofing is an economical option for many commercial building owners when their roof requires repair and restoration because of the energy efficiency of spray foam. It offers a hard, waterproof barrier against rain, hail, snow, and ice. In addition, to its durability, spray foam roofing systems also cuts down on energy bills since the foam insulates the roof and the white topcoat reflects heat from the sun.

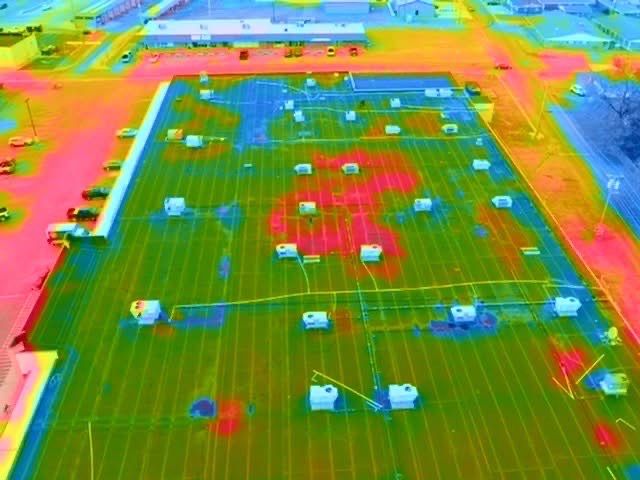

Thermal drone imaging shows where energy is escaping from the roof

Snow is melted in strips on top of the roof which shows where heat is escaping from the building

How It Works: Spray Foam Roofing

Spray foam is a liquid that expands into a rigid, closed-cell foam when applied. This system not only seals your roof but also slashes energy bills, leading to significant energy cost reduction and enhanced structural durability. Spray foam roofing inhibits heat transfer and offers a reflective surface that deflects solar heat. Key components of spray foam roofing systems:

- Polyurethane Foam: The insulating core.

- Base Coat: A protective layer against moisture.

- White Topcoat: Reflects UV rays to reduce roof surface temperatures

At SR Commercial Roofing, we apply a 1.5” layer of spray-on foam (officially known as spray polyurethane foam), followed by a protective base coat and reflective white topcoat. Spray foam insulation combined with a white topcoat can reduce energy use by 30% compared to uninsulated roofs such as metal or rubber with no internal insulation [1]. This system not only seals your roof but also improves energy efficiency and enhances structural durability. At SR Commercial Roofing, we specialize in applying spray foam roofing systems so that building owners can maximize their building’s energy efficiency with a durable roof system.

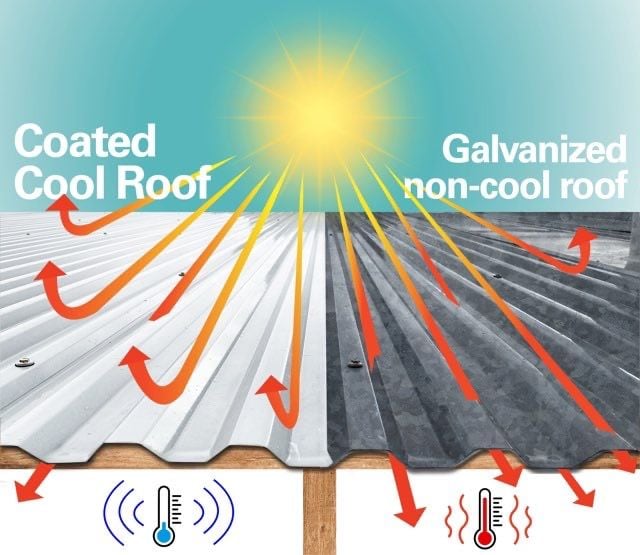

White top coat reflects more of the sun’s rays than a galvanized metal roof

Energy Savings with Spray Foam

How Foam Saves Energy

As mentioned before, the foam roofing system has three components: foam, base coat, and topcoat, all contributing to energy savings with spray foam. Foam and topcoat are the primary factors affecting energy savings. Foam insulates the roof by creating a barrier so that heat has difficulty entering the building through the roof during the summer and escaping from the building through the roof in the winter. The amount of “difficulty” foam or any material creates for heat to escape or enter a building is called R-value.

R-value is the term used to describe a material’s resistance to heat transfer. A larger R-value indicates that less heating and cooling can escape through that material. R-value for foam is 6.5 per sq. in. [2]. At SR Commercial Roofing, we lay 1.5” of cured foam which has an R-value of 9.8 per sq. in. On the other hand, metal roofs that are uninsulated typically have an R-value of 0.34, unless covered with a white coating to reflect extra heat [3]. Rubber roofs usually have an R-value between 0.25 and 0.35 but can reach up to 0.70 in R-value [3]. Which means that spray foam is better than any other roofing system such as metal or rubber roofs when comparing R-values or susceptibility to heat transfer.

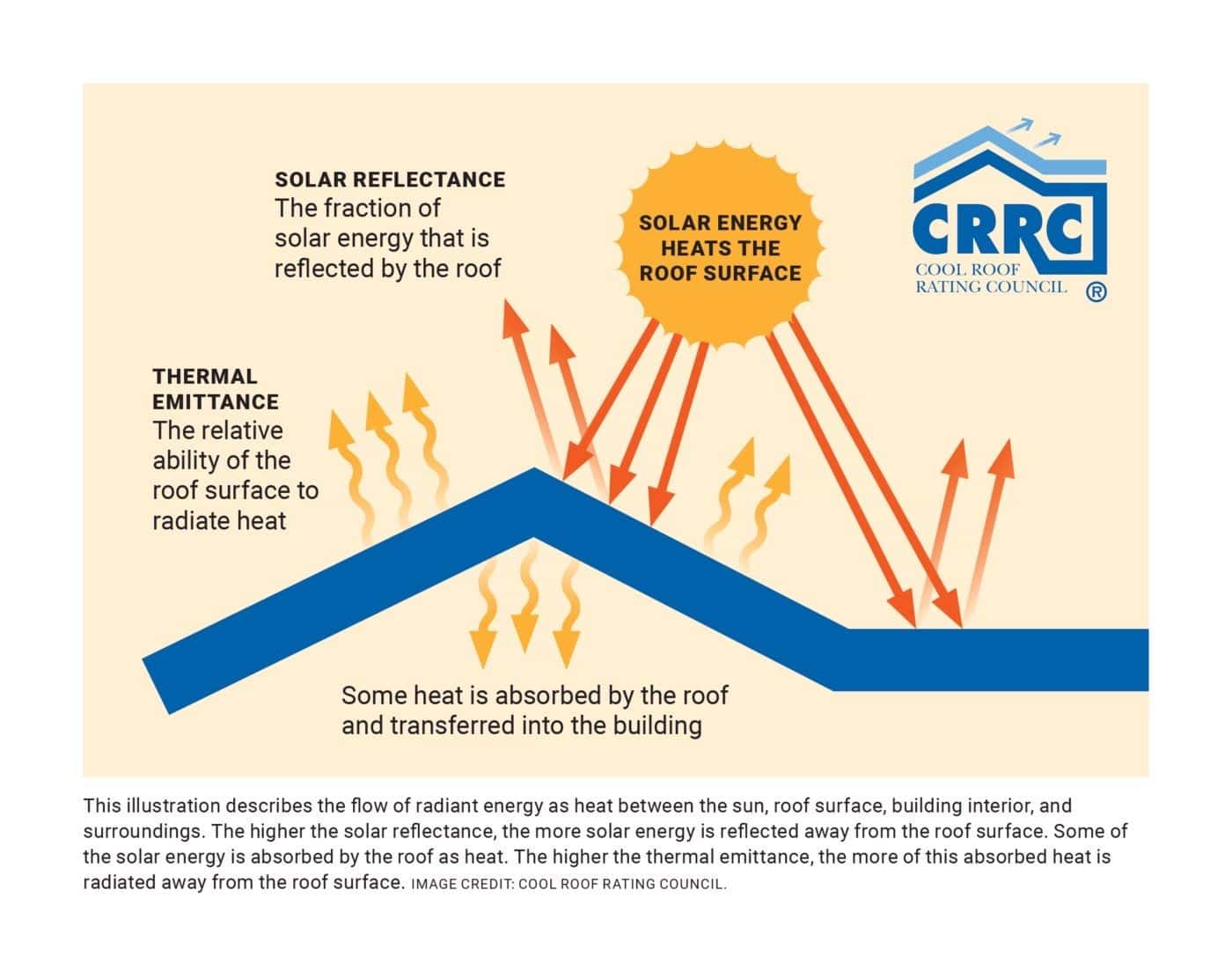

Topcoat accounts for solar reflectance which helps reflect heat back towards the sun. Once the top coat has reflected all it can, the amount of heat that gets into the building is determined by the material’s thermal emittance (similar to R-value). The higher the thermal emittance, the more heat is reflected away from the building (just like a high R-value indicates a good insulator). Metal has a low thermal emittance, but spray foam has a high thermal emitter on the roof to prevent heat from entering the building

The other factor affecting energy savings is the white topcoat. The white topcoat we use at SR Commercial Roofing is sourced from Conklin and can reflect 85% of UV from the sun [4]. By reflecting so much UV, white topcoats can reduce the surface temperature on a roof by 50 degrees [5]. By combining these two powerful protectors against energy loss, a commercial building’s energy bill can drop significantly. Foam protects against losing heating or cooling. The white topcoats reflects back heat from the sun to decrease temperatures on the roof which reduces energy loss to the building and also protects the roof since the roof is not subjected to extreme high temperatures.

The temperature difference between a metal uncoated roof and a white coated Conklin (company where we source our coatings and foam from) roof can be as wide as 80 degrees!

Case Study Example – Texas A&M University

Over the course of 4 years, Texas A&M had 27 buildings (593,500sq. ft.) reroofed with spray foam (or polyurethane foam). They tracked the cost of the reroofing and then annual energy savings [6]. Here’s their numbers:

- $1.7 million spent on reroofing

- $327,500 saved annually in energy bills

- 2 years to pay back roofing expenses with energy savings

Average Savings

The cost to install a spray foam roof varies depending on roof slope, tear-off required, and any special requests. Typically, a spray foam roofing system costs $6-$8/sq. ft. while a metal roofing system often costs $10-$12/sq. ft. Both types of commercial roofs have similar lifespans of approximately 20 years. However, when spray foam roofing systems require repair or replacement, they can often be re-coated for approximately $3/sq. ft. Once they are freshly coated, they can be re-warrantied for another 20 years because the foam under the coating is still intact.

Energy savings on spray foam roofs varies depending on a couple of factors. For example:

- Did the roof have insulation already?

- How efficient is the HVAC for that building?

While these are important questions to answer to figure out how exactly much energy savings to expect from your spray foam roofing system, SR Commercial Roofing offers customized spray foam roofing solutions that typically decrease energy costs by 25-30%.

Additional Benefits Beyond Energy Savings

Besides energy savings, spray foam is less likely to get leaks than metal or rubber roofs because it is sprayed on so that it creates a seamless barrier. Metal and Rubber roofs have weak points at the seams, the edges of the roof, and/or fasteners which are prone to pulling apart, rusting, fasteners back out, etc. which allows water inside the building.

Spray foam offers excellent weather resistance because it withstands hail and does not crack since the material, while very hard, is still flexible. Even if the foam where to be dented by hail, the foam is closed-cell foam which means that the water cannot leak into the building without cutting through the entire 1.5” of foam.

In addition to withstanding hail, spray foam roofing systems withstand temperature fluctuations during the fall and spring because it can flex with the building as the temperature changes without cracking.

Lastly, spray foam is eco-friendly because it decreases energy consumption. Spray foam also reduces waste because spray foam can be re-coated when the warranty is up which decreases the need for tear-off long term.

Installation Process: What to Expect

- Surface Prep

- Foam Application

- Coating Layers

Surface prep may include tear-off (especially for rubber roofs) and power washing to remove debris. Next, any missing screws are replaced and caulked as well as any other areas in need of caulk like around pipes and HVAC. Then the foam is applied. At SR Commercial Roofing, we spray foam twice to achieve the 1.5” thickness of foam. When the foam has set, we spray a base coat which seals the roof against moisture and a topcoat which adds additional protection and reflectiveness of the roof. SR Commercial Roofing’s expert team ensures a meticulous installation process that ensures optimal performance and longevity.

Conclusion

Since spray foam roofing offers durable properties, significant energy savings, and extended lifespan that outperforms traditional roofs, it’s a cost-effective solution for forward-thinking building owners. SR Commercial Roofing’s spray foam roofing systems offer superior protection against the elements while dramatically reducing energy costs.

If you are interested in a spray foam roofing system, contact SR Commercial Roofing at 608-844-4933 for a free roof inspection and quote. Our expert team will help you discover how spray foam roofing can serve you and enhance your building’s energy performance.

Citations

[1] https://www.energyflashroofing.com/spray-foam-roofing/

[2] https://energyshield.net/2022/12/12/spray-foam-cost-vs-benefit/

[3] https://ruggedcoatings.com/understanding-r-value-in-roofing-systems/

[4] https://keystonecommercialroofing.com/what-are-the-different-coating-types-and-colors/

[5] https://www.energystar.gov/products/cool-roofs

[6] https://oaktrust.library.tamu.edu/server/api/core/bitstreams/3cae0982-2935-4a8f-ba92-2e022a104079/content

[7] https://www.armstrong1234.com/the-science-behind-spray-foam-roofing-how-it-works/